Introduction

In recent years, physically discrete fiber connection systems have emerged to respond to a growing demand for security in high-performance fiber networks. While security in the networks can be improved with sophisticated software tools, it is imperative that the right decisions be made in the early stage of the infrastructure design in order to protect the ever increasing amount of sensitive data being exchanged over today’s networks. Actually, risks of unauthorized or inadvertent data changes can be effectively reduced by using proper cabling hardware components. Keyed LC (also known as secure LC) connectivity products are suggested. How could keyed LC solve the problems that only complicated software tools can do? How to use them in the fiber optic network? This article will give you the answer.

Understanding Keyed LC Connectivity Products

The biggest characteristic of keyed LC connectivity products is their various colors. And behind these different colors are different keying features. Each color represents one unique pattern, which ensures that only the same-colored products can be connected to support the data link.

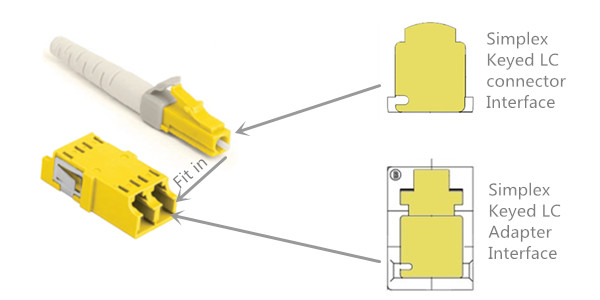

For example, the above picture shows the interfaces of a keyed LC connector and adapter which have yellow color and a unique keying pattern to ensure that they only fit each other. It is clearly showed that the inside structures of the yellow adapter and connector are different from the standard ones and are not compatible with the standards ones. All the other yellow-color LC products including LC patch cable, LC adapter panel and LC cassette which have the same keying feature. In a keyed LC connectivity system, connections can be identified directly by their colors. If the color does not match, the keying feature will prevent the connector from carrying the signal.

Full Series Keyed LC Connectivity Products

Some vendor can provide up to 6, 8 or 10 different colored keyed LC connectivity products. In FS.COM, the keyed LC connectivity products are available in 12 different colors. The above picture shows the 12 different keying features that are identified by colors.

The keyed LC connectivity might be needed in any point of the fiber optic network. To satisfy these requirements and increase the cabling flexibility, a full series of keyed LC connectivity products are introduced in FS.COM, including keyed LC connector, keyed LC adapter, keyed LC patch cable, keyed LC adapter panel, keyed LC fiber optic cassette. The keyed LC adapters are keyed on both the front and back to prevent installation errors and avid a possible security breach. The keyed LC patch cords are offered in multimode 62.5/125 m, 50/125um and laser-optimized 50/125um for the most demanding network performance. They are offered in standard lengths of 2 m (6 ft.), 3 m (10 ft.) and 5 m (16 ft.). Other lengths and configurations may be offered as custom orders. Please note different providers might have different keying pattern, even their keyed LC products are in the same color.

How to Use Keyed LC Connectivity Product in Fiber Optic Network

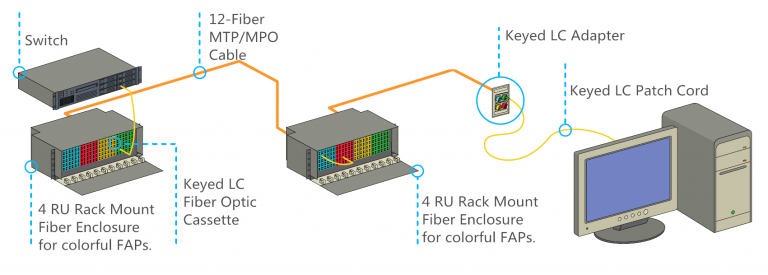

The using of keyed LC connectivity products is not much different from the standard ones. However, they are much more easier for identification and management because of their color-identification system. The above picture shows a typical fiber optic link that is commonly deployed in today’s fiber optic network from data center switch to the target devices.

The keyed LC connectivity solution allows manageable and easily identifiable network segregation by use of a range of physically unique keyed connector and adapter combinations. Each color features a unique keying pattern that only allows matched color mating. As the leading fiber optical manufacturer in China, FS.COM offers keyed LC connectivity products, including keyed LC patch cables, secure keyed LC adapter panels, keyed LC connectors and so on. Other types of high quality fiber cables like SC SC patch cord, SC ST patch cord are also available for your choice.